Advantages of use Eo Sterilizer Chamber

1. It can kill all microorganisms, including bacterial spores.

2. Sterilized articles can be wrapped and packaged as a whole, which can keep sterile before use.

3 in contrast, EO does not corrode plastics, metals and rubber, and does not make items yellow or brittle.

4.It can penetrate irregular articles and sterilize them.

4.It can penetrate irregular articles and sterilize them.

5.It can be used for sterilization of articles that cannot be soaked in disinfectant, sterilized by dry heat, pressure, steam and other chemical gases.

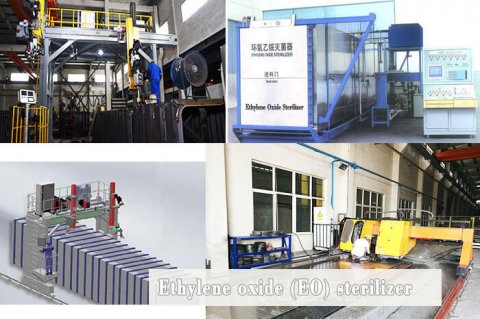

Eo Sterilizer Chamber

| net volume(m3) | Model Number | transport size(mm) | outside size(mm) |

| 3m3 | HMQ-3 | 2300×1550×2350 | 2300×2300×2700 |

| 6m3 | HMQ-6 | 3250×1900×2400 | 3250×2950×2875 |

| 10m3 | HMQ-10 | 4950×1900×2400 | 4950×2950×2875 |

| 15m3 | HMQ-15 | 7200×1900×2400 | 7200×2950×2875 |

| 20m3 | HMQ-20 | 9450×1900×2400 | 9450×29500×2875 |

| 25m3 | HMQ-25 | 10000×1900×2800 | 10000×2950×3800 |

| 30m3 | HMQ-30 | 11500×1900×2900 | 11500×2950×3900 |

| 35m3 | HMQ-35 | 11500×2050×3100 | 11500×3100×4100 |

| 40m3 | HMQ-40 | 13000×2050×3100 | 13000×3100×4100 |

| 50m3 | HMQ-50 | Customized | Customized |

| 100m3 | HMQ-100 | Customized | Customized |

Principle and advantages of Eo Sterilizer Chamber

Ethylene oxide sterilization gas is the most commonly used method of low temperature sterilization. Ethylene oxide sterilization is widely used in the field of sterilization of medical devices. Due to the advantages of active ethylene oxide gas, strong bactericidal power, wide bactericidal spectrum and slight damage to articles, the mixed gas of ethylene oxide and carbon dioxide has become one of the most important daily low-temperature sterilization methods.

Sterilization principle of Eo Sterilizer Chamber

The principle of ethylene oxide sterilization is to alkylate it with sulfhydryl (- SH), amino (- NH2), hydroxy (- OH), carboxyl (- COOH) on protein molecule and imino (- NH -) on nucleic acid molecule, resulting in the loss of reaction group of protein, hindering the normal biochemical reaction and metabolism of protein, leading to the death of microorganisms, so as to achieve the sterilization effect.

Although ethylene oxide has a highly effective disinfection and sterilization effect, its active effect on the container, as well as its irritation and toxicity, resulting in severe use conditions. In order to give full play to the sterilization effect of ethylene oxide and ensure its safety in use, it is popular to mix ethylene oxide and inert gas (freon, carbon dioxide and nitrogen) to reduce the activity of ethylene oxide, so as to improve the safety in use. Since Freon was eliminated due to environmental problems after 2000, the proportion and molecular weight of carbon dioxide are similar to that of ethylene oxide, so 70% carbon dioxide and 30% ethylene oxide are commonly used for sterilization.

Installation of sterilizer

The sterilizer should be placed in a special room. The room shall be connected with power (steam source), water source, drainage and ventilation facilities, and equipped with special grounding device.

Installation position of sterilizer. There should be a certain space around for installation and maintenance; there should be enough space in front of the sterilizer door to ensure convenient access of sterilized articles. Sterilizer should be placed as horizontal as possible.

The gas cylinder shall be connected with a pressure gauge. It is not known that it is close to the heat source or exposed to the sun. The storage temperature shall be less than 50 ℃.

Comments: