The mode of action of ehylene oxide sterilization, the penetrating ability of ethylene oxide sterilization, the technological parameters of EO sterilization, the advantages and disadvantages of EtO sterilization and its cost are discussed.

Mode of action.EO is a penetrating gas.

Medical device product requirements

Package and all parts of product to be sterilized must be gas permeable, irrespective of density

Material compatibility

Widest range of material compatibility except for moisture and temperature-sensitive materials (>30oC and/or <30% RH).

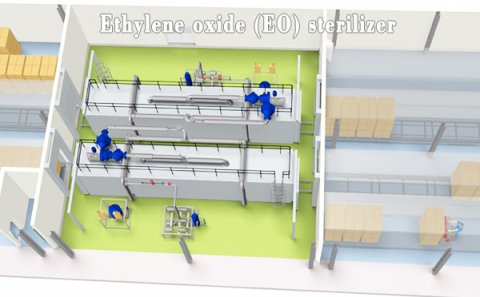

Largest processing unit: Pallets or boxes.

Processing

Product exposed to EO gas, at a defined moisture, pressure and temperature for a validated period of time to achieve the specified SAL.

Tolerance for density variation:Medium

Processing time for a typical 45-ft tractor trailer (~3,000 ft3):1-7 days typical

Processing parameters

There is a need to simultaneously monitor a number of parameters to ensure that the prescribed dose is delivered (e.g. EO concentration, temperature, RH and exposure time).

Product release parameters

In order to release product to market, the following are required:

- Control of the product manufacturing processes to ensure supply of material is consistent with the validated EO process.

- Compliance of the process parameters, monitored independently from the control function, to the validated process specification.

- Routine monitoring and independent release of process using either (1) successful microbiological sterility tests of biological indicators of known resistance prescribed by the ISO standards retrieved from the sterilization load post-process and incubated for typically 7 days and/or (2) routine independent monitoring of critical parameters (EO and relative humidity) as parametric release.

- And any additional tests that may be required: bacterial endotoxin test, product EO residues test and functional product/packaging tests.

Pros (specific to medical devices suitability) EO

- 90-year proven track record.

- EO is compatible with many materials that cannot tolerate or are degraded by radiation sterilization.

Cons (specific to medical devices suitability)

- EO process can leave residuals on products.

- Toxicity issues.

- Safety issue as EO is explosive.

- Medical devices must be packaged in gas- permeable system.

- Cannot penetrate a liquid

- Has difficulty penetrating closed valves.

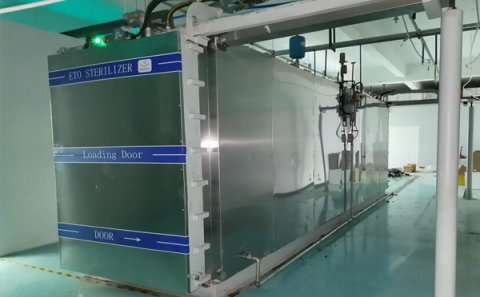

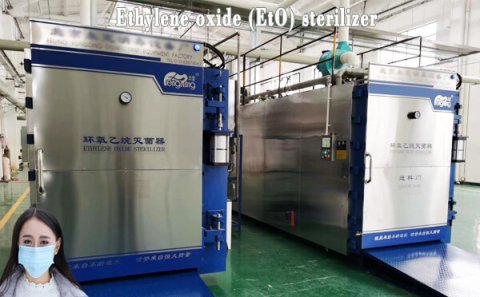

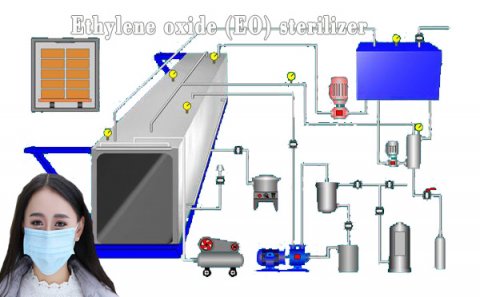

EO sterilizer Equipment

Penetrating capability

Using proper temperature and vacuum pressure conditions, EO has the ability to penetrate most products and product packaging— requires breathable packaging

System repair downtime (e.g.source/system for machine sources; system for Cobalt-60) EO

Mostly scheduled preventative maintenance program often availing of opportunistic downtime between batch processing.

.

Reliability and maintenance

Well maintained chambers and ancillary equipment show stable and reliable performance.

Pros (equipment-related)

Flexible processing only limited by sterilization chamber size.

Cons (equipment-related) EO

- EO is a carcinogenic material

- EO is a flammable and explosive material, which will require properly designed and operated process safety systems.

- Stringent environmental health and safety requirements for EO sites.

- Many supply variables to be controlled and maintained; e.g. EO supply, steam supply, N2 supply, temperature, etc.

- Multiple working parts for complex preventive maintenance schedule.

- EO sterilization facilities are more complex to design and operate.

Sterilization source

Cost of Sterilizers

Includes pressure vessels, pre- conditioning, primary and secondary degassing, air handling, emission controls (catalytic oxidizer and/or scrubber), gas delivery systems, gas storage, EO storage, nitrogen storage and

delivery systems, integrally safe electrics, microbiology laboratory, pallet racking systems and heat generation boiler systems.

Process management

Transport Systems

A combination of automated and manual transportation systems.

Safety Systems

Gas detection systems, fire suppression systems, damage limitation area, integrally safe electrical systems in critical areas. access controls, personnel monitoring systems and personal protective equipment.

Specific Infrastructure

Venting / Shielding

Explosion venting systems are provided in the EO storage and sterilizer areas. Shielding can also be made of concrete and/or steel to form a damage limitation area.

Environmental Authorizations

including federal and/or local environmental permits and hazardous materials licenses.

Ancillary systems

Includes emission controls, boilers, water cooling, compressed air, fire prevention

Common infrastructure

- Land

- Building Warehouse

- Miscellaneous

- fences, racks, furniture, forklifts

- Local authorizations

- Building permits, fire department, environmental regulations such as noise.

Variable costs

Costs that are proportional to production

Operators

Operators typically work in shifts. Moving materials into and out of the Pre Con, sterilization and Degas areas, preparing, placing and recovering BI's. The process is batch based but requires continuous monitoring and supervision

Power

Power Consumption EO plants operate with elevated temperatures, humidity and air handling

requirements. Power is also required to draw vacuums and to process waste EO gas concentrations via an emission control system. All of these processes consume considerable amounts of power.

Spare Parts

Spare parts stock may vary. There are a greater number of support systems that require maintenance and intervention. Spare parts required for the conveyor are similar to gamma, e-beam and x-ray but many other systems require routine maintenance.

Repairs / maintenance and ongoing Investment

Maintenance Engineer General conveyor/electrical maintenance background. The amount and nature of the equipment on site results in high levels of routine operational maintenance.

This article describes the mode of action, penetration ability, process parameters, advantages and disadvantages and cost of ethylene oxide sterilization.

If you have any other questions, please contact us.

Comments: