The characteristics of the eo sterilizer

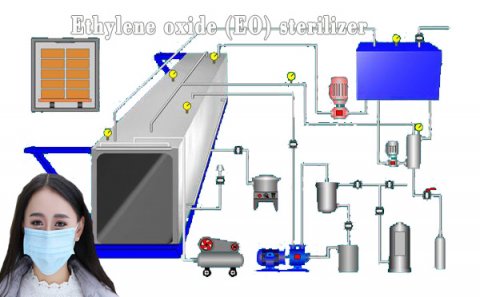

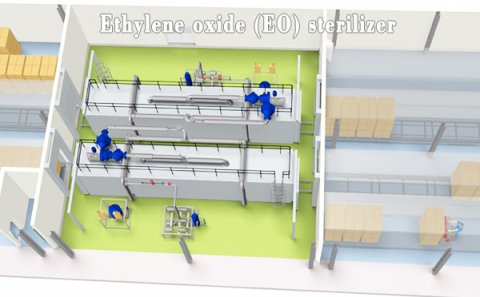

1.operation process by PLC+ industrial computer automatic control, built-in high precision sensor and anti-interference system, circuit detection of temperature, relative humidity, pressure, and set the value to start or stop the relevant equipment system.

2.set arbitrary collection of sterilization interval data, and print out the recorded all sterilization information.

3.parameters can be set in advance, such as: sterilization time, vacuum pumping pressure, EO feeding quantity, sterilization temperature, sterilization humidity, and the parameters can be saved, you can call it for the next sterilization, no need to re set the parameters.

4.the equipment has the following alarm function: a) sensor fault alarm: when the sensor fails there is a voice alarm, and a corresponding text; b) EO feeding quantity alarm: when the inlet charge quantity reaches a preset value, there is a sound alarm, and a text prompt; c) the overpressure alarm: when the pressure exceeds the set value of the sterilizing chamber , there is a sound alarm, and a text prompt; d) ultra high temperature alarm: when the sterilization chamber temperature exceeds the ultra high temperature alarm set value, there is a sound alarm, and a text prompt; E) open and close door alarm: open or close door there is a voice alarm.

5.sealing door adopt the use of pneumatic control, sealed rubber bags used inner inflatable type, fully expanded and the door body calm assurance seal with bag under certain pressure.

6.heating methods use hot water circulation, hexahedron heating, ensuring the sterilization chamber temperature uniformity and temperature control accuracy.

7.insulation in the process when the water tank temperature is lower than the set temperature value, automatically start the compensation temperature of heating system.

8.without damaging the disinfection goods. The sterilizer disinfection, sterilization is basic assurance of goods original characters

9.the equipment is provided with an air filtering device, after sterilization the replacement air with filtered air input sterilizer chamber, to prevent external dust in the air into the sterilizing chamber.

10.the equipment is provided with a gasifying device, EO temperature control, ensure the epoxy ethane from the liquid into a vapor state into the sterilizing chamber.

11.this equipment must be connected with exhaust gas treatment system for the processing of ethylene oxide residue, avoid the pollution of the environment.

12.this equipment belongs to intermittent working system.

The performance of the eo sterilizer

1.Set the temperature range: 30 ~ 70 ℃, the spatial temperature uniformity of no more than plus or minus 3 ℃

2.relative humidity setting range 30 ~ 80% RH, with humidifying function.

3.set the pressure range is from -0.09MPa to +0.12MPa.

4.sterilization chamber under the maximum working pressure of 0.15MPa.

5.Vacuum seal test of sterilization chamber, vacuum degree of 0.09MPa, keep 60min, the change of the vacuum degree is equal to or less than 0.005MPa, positive pressure sealing test of sterilization chamber, pressure 0.12MPa keep 8h, the pressure drop is less than or equal to 0.005MPa.

note:

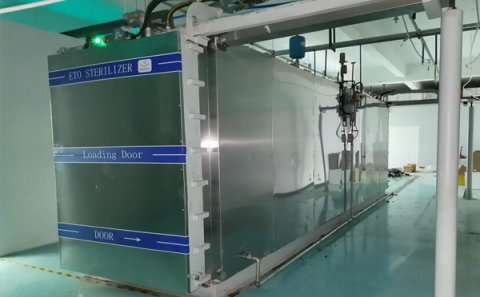

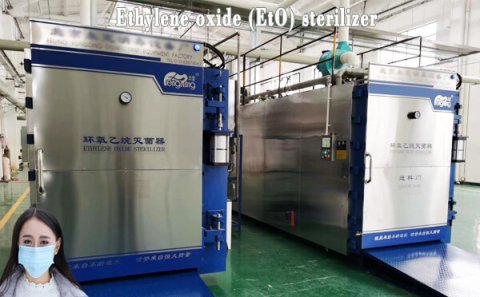

1.Sterilizer according to the user request can be made in single or pass through door according to the agreement;

2.Other specifications volume based on user requirements according to the agreement can be made.

The EO feeding quantity is generally 400 ~ 1200g/m3 (it is pure epoxy ethane input, if mixed gas, ethylene oxide amount shall ensure that meet the requirements in charge);

3.sterilization time is generally 8 ~ 12h.

Note: The main factors that influence the germicidal efficacy of ethylene oxide is the temperature, relative humidity, pressure, vacuum degree, EO feeding quantity, action time and the packing of the product, the product structure, loading mode, initial contaminating bacteria content, and these factors are interrelated, the user should make the sterilization process according to the performance of their products. At the same time, purchase of epoxy ethane gas qualified (certificate of quality shall be provided by the supplier for provide gas).

The scope of application of the ethylene oxide sterilizer

1. medical supplies: syringe, infusion device, dressings, hemostix, catheter type, birth control equipment.

2.medical devices: endoscope, cardiac pacemaker, artificial heart, dialyzer, aspirator, oxygenator replaceable components etc..

3.health supplies: Women's sanitary napkins, paper napkins, disposable tableware etc..

4.Medicine part: Part of Chinese medicine and Western medicine, part cosmetics.

5.textiles and biological products: Cotton & wool chemical fiber clothing, carpets, leather, fur products.

6.RMB, tickets, records, files, books and letters, collection of historical relics, silk satin products, animal specimens.

7.Instruments and meters : electrical instruments , optical instruments, recorder, radio, telephones

Note: The ETO is not permit to sterilize food !

Comments: