1.There was mentioned, that the sterilizing workshop temperature need to be 10’C, Which area will be applicable for this. Plz share dimensions based on 12 cubic capacity.

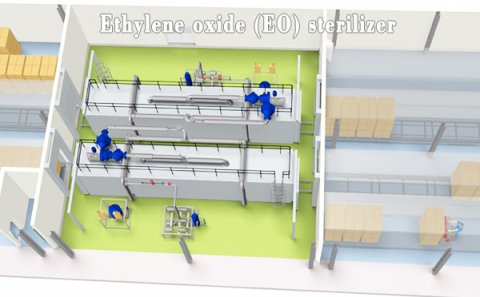

10°C of the workshop is just our suggestion. If you only have one sterilizer. There’s no problem what the temperature is. But if you have aeration room, we suggest to keep the temperature to be at least 10°C ,because if the temperature is too low, the aeration time need to increase. So the aeration room need to be bigger, more energy consumption.

2.Do you supply temperature/humidity control unit for above concern? Plz share quotation + electricity requirement.

Yes, we can provide. If you have steam source, or hot water source( come from local power plant), it will not cost much, less than $5000. But if you don’t have steam or hot water supply. We need to prepare water heating tank .And also more components. It need to be around $10000.

3.During the sterilizing process, that entire area/workshop need to be sealed?

No, it does not need to be sealed. Just far away from fire. It’s critical .

4.Layout: Noted that you are able to provide 3D drawing. Appreciate your support and there need to have more details from machine side to finalize the location/space. After that we will be able discuss with engineer and share the floor plan.

These layout and 3D will be provided after ordered.

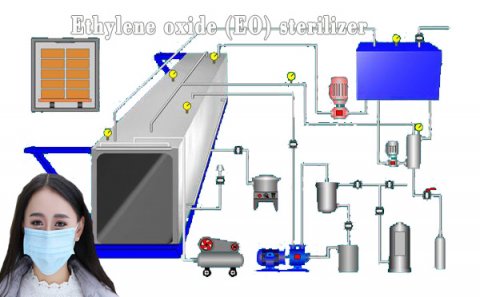

5.What will be the total water consumption per day (consider water jacket around chamber + water which required to neutralize EO after process, etc..). Do we need to maintain water storage? Or can manage with continues supply?

The water jacket only need the first time ,and then to fill a little once a week. But the neutralize barrel will renew each batch. The neutralize barrel is about 700L . Each day two batches. So each day need to consume water 1500L .

6.Gas: Will focus 90%EO/10% CO2. But all the basic equipment needs to suitable to use pure gas 100% EO.

No problem to use 90%EO+10%CO2 gas.

7.Hope all the machine equipment are qualified for that. Plz check and confirm.

I don’t think there’s any problem. Medline required their supplier to buy sterilizers from us. So we know exactly what’s their requirement. But Medline required their customer to have aeration room or aeration chamber.

8.what we need for initial stage – Starting up to make 50,000 garments/day, only with 12m3 Sterlilization Unit.

what you suggest adding on 2nd phase – Aim: To increase the production efficiency ( Add aeration unit )

what you suggest adding on 3rd phase – Aim: To have fully integrated plant. ( Add Preheating unit )

+ if we double the capacity, what will be the additional machine requirement.

First stage if you have the preheating + sterilizing +aeration all three processes running in the sterilizer chamber. Then the second stage , if you want to increase the production efficiency, you can prepare the aeration room. The third stage , we suggest to increase the scrubber, which is your government maybe more strict on envorinment protection.

9.Our recommendation is: first stage, sterilizer + aeration room.

If the budget is sufficient and you plan to do it in one step, it is recommended: sterilizer + preheating room + aeration room.

If the local regulations must be equipped with exhaust gas treatment, exhaust gas treatment equipment should also be purchased.

Don't worry, each of our proposals can meet sterilization requirements.

10.Generally , the sterilizer works 24 hours a day, which is more efficient and consumes less energy.

If the capacity is doubled, the equipment specifications will increase and the price will increase by about 30%-35% .

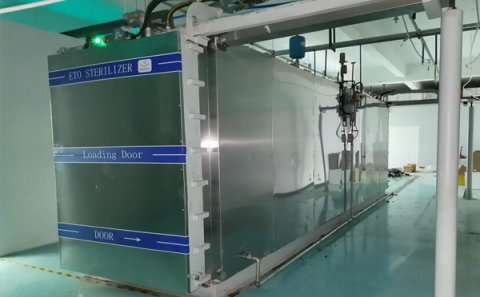

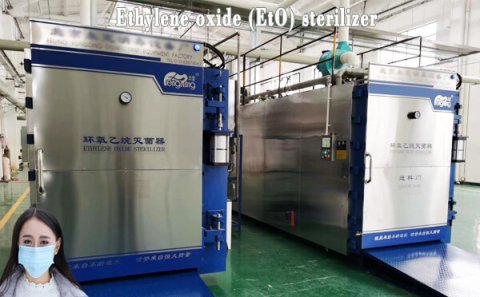

Our factory specializes in the production of ethylene oxide sterilizer, established in 2006, sterilizer sold well in more than 50 countries.

Our factory specializes in the production of ethylene oxide sterilizer, established in 2006, sterilizer sold well in more than 50 countries.

Comments: