Dedicated partners

The latest designs, secure process configurations, intuitive interfaces, and a global service network are some of the reasons to eliminate unplanned outages. From the beginning, he has been a loyal partner throughout the product life cycle, and can minimize downtime through the availability of spare parts and forward-looking support.

In the fast-growing Chinese society, the quality demands for various services and products are increasing. For the increasingly mature Chinese manufacturing enterprises, the trend of more international integration and trade with enterprises of other countries is unstoppable. The sterilization effect control of sterile products is the most important part of its quality control. Without scientific and standard means to ensure the sterilization effect of products, it is difficult to meet the increasing quality demands of the domestic market, and can not be recognized in the international market. Therefore, to standardize the sterilization process and ensure the quality of sterilization has become an urgent task for sterile product manufacturers.

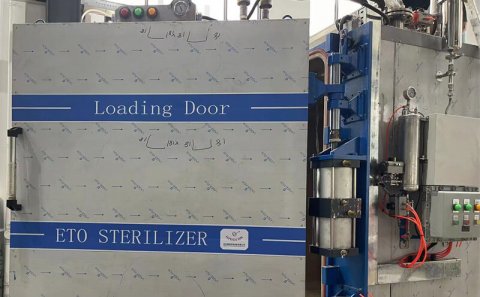

Stainless steel pressure vessels and pipes

From autoclave chamber to process and non process pipeline, it is a solid stainless steel sterilizer. Machine parts are carefully selected to ensure function and hygiene. The panel adopts vertical particle brush and satin coating, which is easy to clean and uniform in appearance. The pressure vessel is welded by manipulator and highly polished.

ETO is a flammable, colorless gas. Four basic parameters (operating range): gas concentration (450 ~ 1200 mg/L); Temperature (37 to 63℃); Relative humidity (40-80%)(ETO was brought to the reaction site by water molecules), and exposure time (1-6 h). These will affect the effectiveness of sterilization of ETO. In a certain range, the increase of gas concentration and temperature can shorten the time needed for sterilization.

The main disadvantages of ETO are long cycle time, high cost and potential harm to patients and staff. Its main advantage is that it can disinfect the heat sensitive or humid medical equipment without harmful effects on the materials used in the medical equipment. Acute exposure to ETO may cause irritation (e.g., skin, eyes, gastrointestinal or respiratory tract) and central nervous system inhibition. Chronic inhalation is associated with cataract formation, cognitive impairment, neurological dysfunction, and multiple neuropathy with disability. Occupational exposure in medical institutions is associated with hematological changes and an increased risk of spontaneous abortion and various cancers. ETO should be considered a known human carcinogen.

Any product must pass the sterilization verification procedure to determine the sterilization process.

Due to the complex process of ethylene oxide sterilization, there are many reasons for its failure, and no classical parameter configuration can be applied to all kinds of situations. In order to ensure the quality of sterilization, it is necessary to carry out strict verification and routine monitoring.

Today, the world leader in ethylene oxide sterilizers using ethylene oxide gas (EO) sterilization, using ethylene oxide sterilizers to sterilize masks makes them safer, more reliable, more convenient and more Economical and more environmentally friendly.

Jul 04, 2022

view: 1877

Presumably, people all know that there are a lot of germs in todays environment. Officially, because of this, the sterilizer industry is expanding from time to time. There are many kinds of sterilizers, including ethylene oxide sterilizers....

Read More

Jun 17, 2025

view: 1464

The sterilizer is used for biological control as a channel between areas. Usually, in the environment with the highest sealing requirements, rooms with double doors are sealed on the wall, forming a barrier between different categories of areas. Cros...

Read More