Because ethylene oxide is flammable, explosive and toxic to people, it must be carried out in a closed ethylene oxide sterilizer.

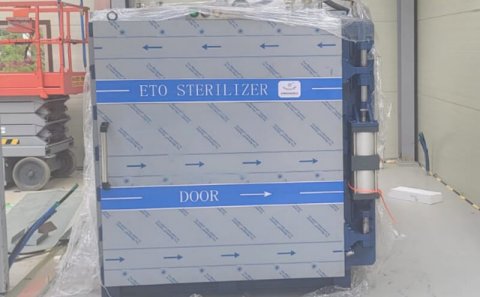

Large ethylene oxide sterilizer

It is generally used for the sterilization of a large number of processed articles. The dosage is 0.8kg/m3 ~ 1.2kg/m3, and it works for 6h at 55 ℃ ~ 60 ℃.

Medium ethylene oxide sterilizer:

It is generally used for sterilization of disposable medical supplies. This kind of sterilization equipment is perfect and highly automatic. It can be used as pure ethylene oxide or mixed gas of ethylene oxide and carbon dioxide.

Generally, the sterilization conditions are:

-

concentration, 800? Mg / L ~ 1000mg / L;

-

temperature, 55 ℃ ~ 60 ℃;

-

relative humidity, 60% ~ 80%;

-

action time, 6H.

Vacuum is required after sterilization.

Sterilized articles are usually sealed and packed with ethylene oxide plastic film. If the small package is equipped with a filter membrane that can filter air, the sterilization effect is better.

Small ethylene oxide sterilizer:

Most of them are used in medical and health departments to deal with a small number of medical devices and supplies. At present, there are 100% pure ethylene oxide or a mixture of ethylene oxide and carbon dioxide. This kind of sterilizer has a high degree of automation, which can automatically vacuumize, automatically add medicine, automatically adjust temperature and relative humidity, and automatically control sterilization time.

ethylene oxide sterilizer process

Ethylene oxide (also known as EO or EtO) is a low temperature gaseous process widely used to sterilize a variety of healthcare products, such as single-use medical devices.

EtO Sterilization process:

Most EtO sterilization lines involve three different stages. These can be separated into three different cells depending on the size or amount of devices to treat:

-

Pre Conditioning

-

Sterilizer

-

Degasser

When cells are separated, automated loading/unloading systems are required. These save operator time as well as giving protection from exposure to a polluted environment, which could be detrimental to health.

EtO gas infiltrates packages as well as products themselves to kill micro organisms that are left during production or packaging processes. This gas, mixed with air at a ratio of at least 3% EtO gas, forms an explosive mixture. Pure EtO gas boiling point is 10.73 oC at atmospheric pressure. Most of the time, it is mixed with Nitrogen or CO2. This explosive condition requires Intrinsic Safe material zoning, for security of people as well as security of the process itself.

Sterilizer Stage

Then the load goes through a long and complex sterilization cycle. Requirements of such a system are:

-

Accurate temperature control.

-

Availability of the control system.

-

Accurate pressure and vacuum control.

-

Easy displays of process phases

-

Dedicated customer recipes.

-

Auto batching release through tolerance tests.

-

Reporting.

-

Security interlocks between actuators.

-

Alarming.

-

Shut down strategies.

-

Audit Trail facilities – Trending.

-

HMQ 21CFR Part11

As part of our ongoing efforts to expedite approvals of certain changes to ethylene oxide sterilization processes & facilities, the HMQ announced its first Master File acceptance into the HMQ Ethylene Oxide Sterilization Master File Pilot Program.

ethylene oxide sterilizer manufacturer

We are Ethylene oxide sterilizers manufacturer, the perfect method for medical device sterilization.Focusing on the R & D and manufacturing of ethylene oxide sterilization equipment, it is located at Caitong Zhongxin, Xiasha District, Hangzhou city, Zhejiang Province . The company has a history of more than 15 years and is in a leading position in market share, enterprise popularity, product quality and technical level in this field. The company mainly produces ethylene oxide sterilizer (HMQ series products), file (cultural relic) sterilization equipment, preheating, analysis, waste gas treatment and other supporting products, and provides technical services related to ethylene oxide sterilization. The company is the first domestic certified manufacturer that has developed an ultra large 100 cubic meter ethylene oxide sterilizer. It has dozens of products of different sizes (HMQ-100 m3, 80 m3, 50 m3, 30 m3, 20 m3, 10 m3, 6 m3, 3 m3, 1 m3, etc.), which are exported to more than 30 countries and regions.

ethylene oxide sterlizer machine Process

1. Environmental Preconditioning

Most of the EO sterilization processes of today start with conditioning of the products to be sterilized outside of the sterilization chamber. Preconditioning is usually performed in a room which has been specially designed to heat and humidify the products to a stable internal temperature and moisture content prior to entering the chamber. This will assure that the sterilization process is reproducible regardless of external influences such as varying climatic conditions.

Items for consideration:

-

Be aware of the need to heat and humidify the product for 12 to 72 hours. Packaging integrity and its ability to withstand preconditioning conditions of a nominal 118°F (47°C) and 65 percent relative humidity must be taken into consideration. Emphasis should be placed on corrugate strength and stability over time in the harsh environment.

-

Once preconditioning is complete, the products are placed in a heated chamber which has been designed to withstand the extreme pressures realized when delivering the sterilization process.

2. Initial Evacuation

To safely deliver the 100% ethylene oxide process, at least 97 percent of the air must be removed from the chamber. Today, the two most common methods of accomplishing this requirement are (1) pulling a deep vacuum, or (2) performing a series of partial vacuums followed by a series of nitrogen injections. This combination, when performed using an adequate number of repetitions, will purge (remove) the air, thus allowing the process to be performed safely.

Items for consideration:

-

The initial vacuum rate is designed and controlled for the product and its ability to withstand pressure changes. The evacuation rate is selected to assure package integrity is maintained by allowing the air trapped inside the package to vent without destroying the seal integrity. This will assure that the package’s sterile barrier properties are maintained, thus ultimately protecting the sterility of the product once the process is complete.

-

The amount of negative pressure (vacuum) designed into the process is dictated by the pressure sensitivity of the product. Some devices and/or components are not designed to withstand deep vacuums and/or high pressures. Subjecting them to the extreme pressures required to deliver a deep vacuum or 100% EO process will result in burst packaging and damaged products.

-

For those pressure sensitive products, the shallow vacuum or nitrogen soft cycle is utilized for processing. During a nitrogen soft cycle, an initial shallow vacuum is drawn followed by a nitrogen injection. The combination of the vacuum and nitrogen injection is called a nitrogen wash. This process is repeated several times (several nitrogen washes) to assure an adequate removal of air from the vessel.

-

Although less demanding on packaging seal integrity, the nitrogen soft cycle is the less desirable when compared to the 100% EO process. By performing the additional washes, which are required for safety purposes, additional time is added to the total process. This delays product release and, when using a contract sterilization service, adds additional cost which is based on actual sterilizer time.

3. Humidification

The total inactivation of microorganisms using ethylene oxide is attained when sterilizing conditions are met within the chamber. The four active ingredients required to deliver a successful process are:

-

Heat

-

Moisture

-

Gas concentration

-

Time

During the previous preconditioning step, heat and moisture were added to the product to a predetermined or stable condition. When the initial evacuation phase of the process is performed, the product can lose a significant amount of moisture. This moisture must be replaced prior to introducing the ethylene oxide. This is accomplished by adding humidity in the form of steam injections. The amount of steam required is calculated to yield a predetermined relative humidity3. After the addition of steam, the product is allowed to dwell or soak for the amount of time required to replace the moisture lost from the evacuation phase.

Items for consideration:

-

The humidification phase of the process can subject the product to elevated levels of moisture and heat. Care should be taken when selecting packaging to assure that the corrugate strength is adequate to withstand the process.

-

The levels of moisture are determined by the process design scientist to assure adequate moisture content within the product for sterilization purposes. Care is exercised to prevent overheating when injecting steam. It is extremely important to identify any temperature limitations prior to initial process design. If necessary, the process design scientist can adjust cycle parameters of an existing processes to compensate for product sensitivity to heat. The cost of the adjustment may be added time to the entire process.

4. Gas Injections and Gas Dwell

After the humidification phase, liquid ethylene oxide is first heated into a gaseous phase, then injected into the chamber. The amount of gas or gas concentration3 is dependent on two primary factors which are addressed during cycle design.

The most important factor is to assure that the minimum gas concentration required to achieve sterility within the product is attained. This minimum concentration must be balanced against the second factor, which is the maximum amount of gas that can be injected before difficulties arise due to high levels of post-sterilization EO residuals.

After the gas has been injected, the exposure phase of the process is performed. This is the phase in which the product is exposed to heat, relative humidity, and gas for a predetermined amount of time. As a rule of the thumb, the more difficult the product is to sterilize, the longer the exposure time. The amount of exposure time is determined by the process design scientist, after careful analysis of the product, load configuration, and desired level of sterility. Preliminary laboratory experiments may be needed prior to validation execution.

Items for consideration:

-

The time expended for the exposure phase of the process is dictated by the ability of the gas to penetrate or soak into all areas of the product required to be sterile. Careful consideration of the sterilization method during product design will ultimately result in an optimized sterilization process, which will save time as well as reduce the costs of processing.

5. Postexposure Gas Purge and Air Inbleed

After the exposure phase of the process, all gas must be removed from the chamber until the levels of EO fall below the flammable limit for the gas (3 percent or 30,000 ppm). This is accomplished by performing a series of post-vacuums, each followed with a nitrogen backfill (wash).

A maximum working pressure for the washes is selected by the process design scientist to assure that the products, which may have been softened during the exposure phase of the process, will not be damaged. An ample number of washes is performed to reduce product residues and facilitate safe handling of the product after processing.

Items for consideration:

-

Postexposure washes are very similar to the washes performed during initial evacuation for shallow vacuum nitrogen soft cycles. However, in the case of the 100% EO processes, the procedure is similar but deeper vacuums are utilized.

6. Heated Aeration

To reduce the amount of residence time in the vessel, products after sterilization are usually placed in a heated room for additional removal of the residual gases. The rooms are maintained at elevated temperatures and the outgassed residues are continuously removed from the room and scrubbed. The aeration rooms help contain any airborne EO and continually reduce the in-product residues. After aeration, the load is moved to the warehouse for storage until release.

Items for consideration:

-

The additional aeration time and heat accelerates the outgassing process. The amount of time required to clean the products is a factor of the product material composition and the intended use of the device (blood contact, mucus membrane contact, topical, etc.). New guidelines are due to be published from the Association for the Advancement of Medical Instrumentation (AAMI), which will provide additional guidance for the ISO 10993-74 standard currently in use in the United States and on international markets.

ethylene oxide sterilizer manufacturers in China

We are Ethylene oxide sterilizers manufacturer, the perfect method for medical device sterilization.ethylene oxide sterilizer for sale.Since 2006, as the first drafting unit, the company has drafted 11 national and industrial standards such as ethylene oxide sterilizer, which is the unit of the chairman of the national disinfection technology and equipment standardization committee. The company has passed the medical device quality management system certification of Beijing Huaguang, and is a national high-tech enterprise, Hangzhou "young eagle plan" cultivation enterprise and Zhejiang high growth technology SMEs. The company has also obtained a number of national invention patents and utility model patents.