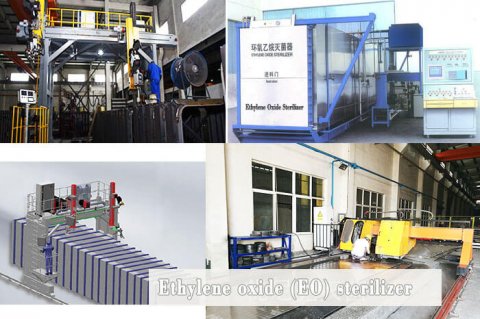

LE Series EO sterilizer

The brand, quantity of parts , function, control system , overall standard of BE, LE and GE series are different, so are the costs.

These three series are different. Customers can choose one series according to functional requirements.

-GE series has the highest price because of its high configuration, full functions and the most detailed reports.

-LE series, can meet the needs of most customers, low price.

-BE series, the lowest price, suitable for customers with less capital budget.

Description Relevant Technial Parameter of LE Series

system design standard: EN1422. ISO11135-2014

body (main part) LE Series EO sterilizer

1. Cabinet:stainless steel SUS304,δ=6mm

2. water jacket: U-bar carbon steel (bottom is stainless steel)

3. housing:stainless steel

4. foot: U- bar steel 14#/Q235

5. foot support: steel sheet 10/Q235

6. insulating layer: ceramic fiber

door (main part) LE Series EO sterilizer

1. door: stainless steel : SUS304,δ=6mm

2. door frame:rectangular steel 120*60/Q235

3. door water Jacket: U- bar carbon steel

4. door seal flange: carbon Steel

5. housing:stainless steel

6. insulating layer:ceramic fiber

heating components (main part) LE Series EO sterilizer

1. frame:angle steel 50×50×3

2. heating water tank: stainless steel

3. housing of tank: stainless Steel

4. electronic heater: stainless steel electrical heating pipe

EO vaporizer

1. vaporizer liner:stainless steel

2. EO coil pipe:stainless steel pipe SUS304

3. vaporizer housing:stainless steel

4. insulating layer:fireproof aluminium silicate fiber blanket

EO feeding device pressure gage,mannual valve , Filter , connecting pipe

Standard Components LE Series EO sterilizer

Description Specification & ParameterBrand

-

heating pipe: 3*3kw/AC380V 3P

-

vaccum pump: 1.45kw/AC380V 3P 50HZ

-

vaporization pump: AC220V/200W 2P 50HZ

-

safety valve: 0.15Mpa1

-

steam generator: 3KW/AC380V 50HZ

-

air compressor: 1.5Kw/AC380V 3P 50HZ

-

magnetic valve DC24V

-

pneumatic valve EO sterilizer

-

humidifying valve: 20mm screwed fitting

-

vacuum valve: 1inch screwed fitting

-

Feeding EO valve:20mm screwed fitting

-

Feeding N2 valve:none

-

air release valve:1 inch screwed fitting

-

steam heating valve: none

EO electric scale

1. range: 100Kg;

2. material: stainless steel;

3. support RS485 communication function;

Control System LE Series Description Specifications

temperature sensor

output form:PT100;

range:-50~100℃

pressure sensor

output form:4~20mA

voltage: DC24V

range:-0.1~+0.15Mpa

humidity sensor

output form:4~20mA

voltage: DC24V

range: 0~100%RH

control cabinet: integrated work station BGIB2-E01

control module: SIEMENS S7200 PLC/SMART

screen: TK6050IP

low voltage apparatus: SCHNEIDER

buttons and indicator light: SCHNEIDER

IPC(Industrial Personnal Computer): SMART IPC3000

screen: 226V6QSB6/21'5/16:9

printer: Deskjet 2020hc Color Ink-Jek

UPS: 1000VA SANTE

System Function LE Series

-

system design standard: EN1422. ISO11135-2014

-

system control mode: by switching. Soft mannual & Full- Automatic

-

open/close Door way: pneumatic revolve door

-

door qty: one

-

data record way: interval mode , warning triggered mode

-

historical curve record way: continuous time interval mode

-

data save time: 10 years(If hard drive is not damaged)

-

recirculated water connector: boht cabinet and door with one way in and one way out

-

circulation water jacket replacement time: <5 minutes

-

temperature sensor precision: display Range: 0-100℃;resolution: 0.1℃

-

temperature control precision: cabinet wall temperature difference within ±5℃, cabinet inside temperature difference is within ±3℃

-

pressure sensor precisiondisplay: Range : -100-+150Kpa,resolution: 0.1Kpa

-

vaccum control mode: continuous mode and stepping mode ( proportional valve regulating mode is choosable)

-

vaccuming time: <30minutes from 0 to -90KPa

-

humidity sensor precision: display range: 0-100%RH(no-condensing) , resolution 0.1%RH

-

control time range: 0-99hours, sterilizing time resolution 1min

-

cabinet water volume auto detecting yes ,system shows and controls the water volume and feeds water automaticly.

-

steam heating connector: yes, auto control

-

steam detecting: yes, displaying and warning when the steam is not enough

-

vaccum pump detecting connector: yes, displaying and warning when the pressure is not enough

-

steam pressure detecting connector: yes, displaying and warning when the pressure is not enough

-

humidifing connector: yes ,humidifying automaticly by pulsatile mode

-

humidifying way: pressure difference or sensor

-

Nitrogen protection system connector: yes , auto control

-

tail gas treatment connector: yes , auto control

-

in-door and out-door air exhausing connector: yes , auto control

-

data record and dealing mode: PC monitoring software and sterilizing Data report software

-

over high temperature limit protection: yes

-

over high pressure limit protection: yes

-

EO under low temperature limit protection: Yes

BOCON is a large-scale manufacturer of ethylene oxide sterilizer. We can customize and produce ethylene oxide sterilizers to meet all the needs of customers.

Jul 04, 2022

view: 1231

Presumably, people all know that there are a lot of germs in todays environment. Officially, because of this, the sterilizer industry is expanding from time to time. There are many kinds of sterilizers, including ethylene oxide sterilizers....

Read More

Jul 15, 2021

view: 1840

EO sensor.This can be achieved by using independent control and monitoring systems, or by cross checking between control and monitoring to identify any differences or indicate faults. If there is no detected fault in the control or monitoring functio...

Read More