Simple but effective

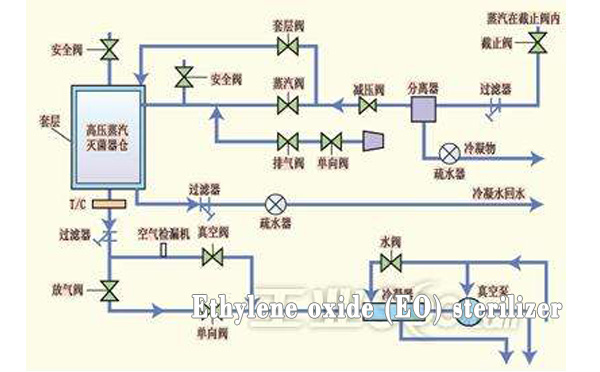

When pure ethylene oxide vapor (100%) is mixed with air whose volume fraction is only 3%, it is flammable and explosive. In order to safely use gas as an industrial disinfectant, the process

It is designed as a cycle stage, and its conveying mode does not allow the process to enter into unsafe state.

This process can be described in a very simple form, as follows:

Using the vacuum chamber, draw in the initial vacuum to exhaust the air and prevent the injection of ethylene oxide

Into an unsafe mixture. After vacuumizing, water is usually added to the vacuum chamber in the form of steam to replace the water lost in the initial vacuum stage.

The next step of this step is to introduce ethylene oxide gas into a predetermined concentration. Select the concentration to ensure proper sterilization. Finally, the product is soaked in ethylene oxide for control

After the scheduled time, a series of cleaning operations are performed to remove the EO chamber. Cleaning involves vacuuming and then pressurizing with inert gas (usually nitrogen). heavy

The re vacuumizing and pressurizing process is scheduled until the indoor air is below the 3% flammability limit of EO.

Gas injection and gas reservoir

After the humidification phase, liquid ethylene oxide is first heated to the gas phase and then injected into the chamber. Gas or gas concentration 3 depends on two main factors, both of which are involved in the cycle design.

The most important factor is to ensure that the minimum gas concentration required for product sterility is achieved. This minimum concentration must be balanced with a second factor, which is the maximum atmospheric volume that can be injected before the high concentration of sterile ethylene oxide residue makes it difficult.

After gas injection, the exposure phase of the process is carried out. At this stage, the product is exposed to heat, relative humidity and gas for a predetermined period of time. According to experience, the more difficult the product is to sterilize, the longer the exposure time. After careful analysis of the product, load configuration and required sterility level, the exposure time is determined by the process design scientists. Preliminary laboratory tests may be required prior to validation.

Principle and advantages of ethylene oxide sterilization

Ethylene oxide sterilization gas is the most commonly used method of low temperature sterilization. Ethylene oxide sterilization is widely used in the field of sterilization of medical devices. Due to the advantages of active ethylene oxide gas, strong bactericidal power, wide bactericidal spectrum and slight damage to articles, the mixed gas of ethylene oxide and carbon dioxide has become one of the most important daily low-temperature sterilization methods.

Workshop conditions for sterilization

Generally, EO sterilizer needs EO Room, Auxiliary Room and Control Room.

Standard requires that the door of EO room cannot lead to sterilization workshop.

1. The whole sterilization workshop it is forbidden to open fire, away from the fire. Solid ground level.

2. Sterilization workshop shall ensure the temperature over 10 degrees Celsius (heating in winter).

3. The sterilizer room should guarantee the well ventilated, use explosion-proof lamps and lanterns and switch.

4. The sterilizer room, explosion-proof axial flow fan, installed in 300-500 mm off the ground.

5. EO room should be well ventilated, avoid direct sunlight, use explosion-proof lamps and lanterns and switch

6. EO room /control room /Auxiliary room height 3000mm(min).

Our company's ethylene oxide sterilizer is the best choice for mask manufacturers. Ethylene oxide sterilizer is the most professional tool for sterilizing and disinfecting medical masks and disposable civilian masks.

The size of our company's ethylene oxide sterilizer can be customized. Depending on the scale, different sizes of ethylene oxide sterilizers can be provided. Generally speaking, ethylene oxide sterilizers have several different specifications, such as 3 cubic meters, 6 cubic meters, and 10 cubic meters.

Mar 08, 2020

view: 1443

Sterilization principle Ethylene oxide (EO) is a highly effective gas sterilizing agent, which has been widely used in the sterilization of heat and humidity sensitive medical devices since 1950s. Its liquid state and gas state have sterili...

Read More

Oct 29, 2020

view: 1003

The specifications for the sterilizer and the sterilization process; a) IQ / OQ data; b) Physical and microbiological records of the entire PQ run; c) All pressure gauges and recorders have been calibrated and within the validity period. d) Regulatio...

Read More