EO History

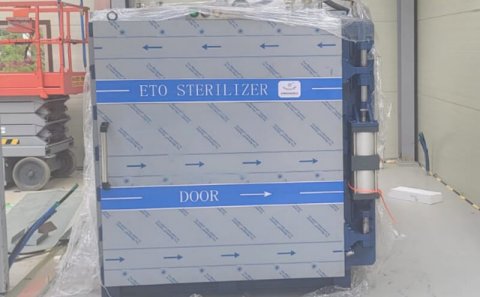

More than 30 years ago, this technology was developed for the sterilization of heat and humidity sensitive materials. It is the best choice for sterilization of surgical precision medical devices, optical instruments, electronic equipment plastic products, etc. in 1965, 100% ethylene oxide gas (EO) sterilizer was first launched, with its continuously improved technology and unique products, to ensure the safety of operators and protect the environment from pollution.

EO Latest Achievements

Today, it has become a world leader in 100% ethylene oxide gas (EO) sterilization, making it safer, more reliable, more convenient, more economical, and more environmentally friendly. 3M has been a 100% EO supplier since 1965, offering different sizes depending on the size of the hospital. The entire sterilization process is completely in a negative pressure state to ensure that the gas does not leak out. The built-in temperature probe can adjust the temperature immediately. The built-in humidity probe ensures relative humidity> 65%. The built-in exhaust device completes the highly intelligent control of sterilization and exhaust. Computerized operation. Obtained UL, TUV, CE, CSA agency test box evaluation requirements. Helps you control load and turnaround time to meet peak usage needs. Multiple installations allow simultaneous sterilization and automatic venting. Embedded wall mounting and freestanding shelves can install multiple sterilizers at the same time, saving time and effort, and saving space. The world's first 100% EO gas single-dose gas tank manufacturer.

Advantage Of EO

Convenient transportation and storage, no need of huge gas cylinder, no need of filtering gas, more importantly, CFC free. Environmental protection and safety.

1. It can kill all microorganisms, including bacterial spores.

2. Sterilized articles can be wrapped and packaged as a whole, which can keep sterile before use.

3 in contrast, EO does not corrode plastics, metals and rubber, and does not make items yellow or brittle.

4.It can penetrate irregular articles and sterilize them.

5.It can be used for sterilization of articles that cannot be soaked in disinfectant, sterilized by dry heat, pressure, steam and other chemical gases.

the process characteristics of ethylene oxide sterilization

The ETO sterilizaton process is used to sterilize medical devices and other items sensitive to heat or moisture.

The basic ETO sterilization cycle consists of 5 stages (i.e., preconditioning and humidification, gas introduction, exposure, evacuation, and air washes) and takes approximately 8-10 hrs excluding aeration time.

In addition, Determine whether to use ethylene oxide sterilization based on product material and packaging type.

For products that are not compatible with high temperatures and ionizing radiation, ethylene oxide sterilization is a good choice. Due to its low-temperature process that can prevent material deformation or oxidation, ethylene oxide sterilization has a wide range of applications in medical device processing.

EO sterilization has the advantage of being compatible with multiple materials and is suitable for products that cannot withstand high temperature sterilization. Ethylene oxide can penetrate into the smallest gaps of the items to be disinfected. This feature allows it to be used on already packaged materials.

Products and packaging made from different materials require different sterilization processes.

Jun 17, 2025

view: 1119

In practical applications, the rate can be determined as the time (with tolerance) required to achieve a specified pressure change. a) The minimum temperature at which the product enters the sterilization process and / or the specified conditions req...

Read More

Jun 17, 2025

view: 1937

The brand, quantity of parts , function, control system , overall standard of BE, LE and GE series are different, so are the costs. Description Relevant Technical Parameter of BE Series Ethylene Oxide Sterilizer. BE Series Ethylene Oxide Sterilizer s...

Read More