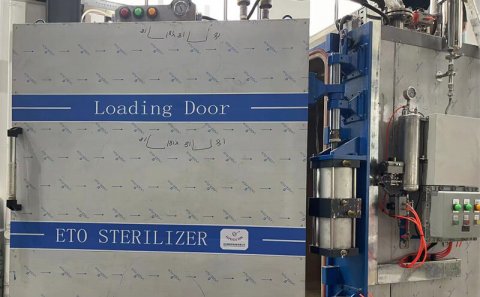

Manufacturer of EO sterilizer machine for mask

Today, the world leader in ethylene oxide sterilizers using ethylene oxide gas (EO) sterilization, using ethylene oxide sterilizers to sterilize masks makes them safer, more reliable, more convenient and more Economical and more environmentally friendly.

Our company's ethylene oxide sterilizer is the best choice for mask manufacturers. Ethylene oxide sterilizer is the most professional tool for sterilizing and disinfecting medical masks and disposable civilian masks.

Analysis process of EO sterilizer machine

Analysis: use ventilation and heating system to separate the EO gas adsorbed on the product.

After the sterilization stage is completed, the processed products are moved into the analyzer room

The analyzer room is equipped with heating system, circulating air system and exhaust system

Temperature, exhaust clearance and time can be controlled automatically

Operate according to the validation time of sterilization process, separate the EO gas adsorbed in the product, and make the residual EO content of the product meet the requirements.

The temperature of forced resolution can reach 50 ℃, the resolution of 6-12 hours, EO residue completely meet or even exceed the verification requirements!

Waste gas treatment system of EO sterilizer machine.

The waste gas treatment system is set in an independent treatment room, which is used to treat the ethylene oxide waste gas extracted from the sterilization cabinet. The EO waste gas is respectively treated by strong acid, strong alkali and acid-base mixture, and then discharged into the water tank for four times. Environmental protection, energy conservation, safety, and treatment effect meet regulatory requirements.

Standard production of EO sterilizer machine

Due to the complex process of ethylene oxide sterilization, there are many reasons for its failure, and no classical parameter configuration can be applied to all kinds of situations. In order to ensure the quality of sterilization, it is necessary to carry out strict verification and routine monitoring.

In the fast-growing Chinese society, the quality demands for various services and products are increasing. For the increasingly mature Chinese manufacturing enterprises, the trend of more international integration and trade with enterprises of other countries is unstoppable. The sterilization effect control of sterile products is the most important part of its quality control. Without scientific and standard means to ensure the sterilization effect of products, it is difficult to meet the increasing quality demands of the domestic market, and can not be recognized in the international market. Therefore, to standardize the sterilization process and ensure the quality of sterilization has become an urgent task for sterile product manufacturers.

Jul 04, 2022

view: 1567

Presumably, people all know that there are a lot of germs in todays environment. Officially, because of this, the sterilizer industry is expanding from time to time. There are many kinds of sterilizers, including ethylene oxide sterilizers....

Read More

Jun 17, 2025

view: 1723

Why use ethylene oxide sterilization cabinet? In hospitals,health centers and other places, ethylene oxide sterilization cabinets are often used to sterilize articles. We know that there are many kinds of sterilization equipment in medical research,...

Read More