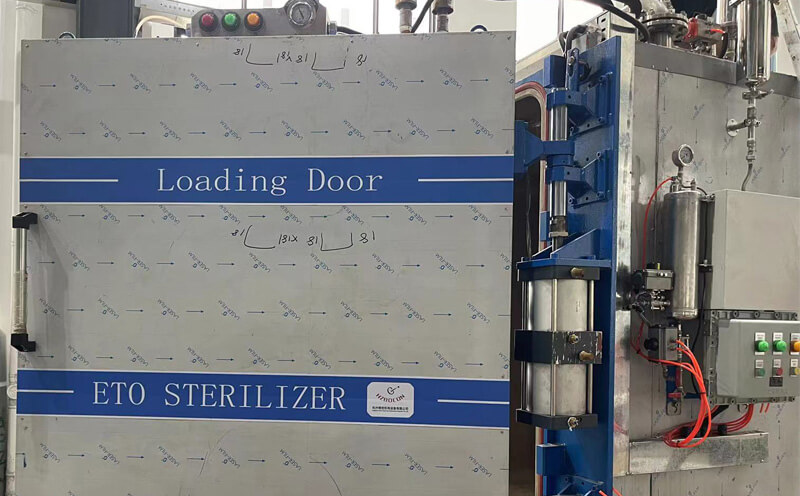

Safety inspection of epoxy ethane sterilizer

equipment is complete and in good state

Sterilizer used must remain intact state, especially the sterilizer air tightness, cleanliness, integrity.

leakage check

In the ethylene oxide sterilization, should be regularly checking the leak on sterilization cabinet and corresponding pipeline ( available with 1% phenolphthalein sodium thiosulfate solution soaked test paper, affixed to the suspected leak part, such as test paper turns red, which is proved to have ethylene oxide leakage).

emergency treatment for the failure in the process of sterilization

1. in eo feeding process such as the discovery of eo feeding pipeline leakage, should close the feeding valve on bottle and on the host immediately, open axial flow fan, make the air circulation, and then repair.

2. in the sterilization, such as after feeding eo, the discovery of gas leakage on the cabinet, should immediately stop the sterilization and make vacuum, after the cabinet body of epoxy ethane evacuation, then repair.

3. The use of internal circulation system foundabnormal sound andtemperature overheating phenomenon, should immediately stop the work.

4 if the sterilization process found abnormal increase of pressure in the cabinet, should immediately stop work, identify the reasons, troubleshooting before operation.

Sterilizer Maintenance Guide

1.sterilization operation personnel shall not leave the scene, should observe the sterilization situation at any time, if has the abnormal phenomenon, immediately shut down and cut off the power supply, check.

2. Supply voltage of computer and control cabinet shall be in the range of 210 ~ 240V, power supply circuit should be far away from the power supply circuit of power equipment.

3. To clean up steam pipeline and eo feeding pipeline of the sterilizer every time before sterilization , and will release the water and foreign matters filtered by steam filter .

4. every time before starting the equipment, inspect level of the water tank, the water level shall not be lower than the glass tube 2/3, so as not to damage the heating element.

5. to ensure adequate water to the steam generator, otherwise it will affect the service life.

6. When power failure can not open the computer, otherwise it will be depleted the battery energy of uninterrupted power supply.

7. once open the computer, to close, must be carried out according to the process, can not directly to power off the computer.

8. if sterilization cabinet long time does not work must turn off the total power supply cabinet.

9. the printer from the front paper feed, be sure to make paper close to the feeder right side, in order to avoid paper jams.

10. avoid by all means install other software programs on this computer, the absolute prohibition of playing games, so as to avoid infection of virus, otherwise responsibility by yourself.

11. every week to verify a sterilizer cabinet air tightness: in the sterilizer no-load, under the condition of constant temperature, vacuum pumping to -50kPa, pressure keeping for 1 hours, the leakage rate should be less than or equal to 0.1kPa/min, otherwise the cabinet has leakage, check leakage point and repair.

12. every week check internal circulation impeller integrity, fastening screws, every month for feeding bearing grease U6 one time, if has the problem please timely replace.

13. every week check reliability of each wiring terminal of console , electric control cabinet, control frame. In the sterilizer shutdown power-off state, touches each wiring terminal connection with hand or other tools, see the contact is firm, if there are loose should be tightened immediately.

14. in accordance with the relevant provisions of National Metrology Law, sensor and instrument should be regularly sent to the local measuring department for verification.

15. heating system Circulating water every 6 months to replace one time.

16. according to the use frequency of the sterilizer, at least every six months to replace sealant.

17. every week, check the sealing condition of gas valve, such as leakage should be fastened or change the sealing ring.

18. every time before sterilization, should check the pressure relief valve the pressure relief value is correct, if error should be adjusted in time.

19. Clean through the eo feeding pipe once a year .

20. according to the quality of the sterilizing agent, epoxy ethane filters should be cleaned on a regular basis.

21. according to the actual situation of the working environment keep the regular cleaning or replacement of air filters.

22. regular cleaning of dirt in the eo inlet of cabinet .

23. Feed water of the water ring vacuum pump same time of start the vacuum pump, otherwise easy to damage the vacuum pump

24. please refer to the manufacturers of steam generator with the instructions for use, correct use of it.

Jun 17, 2021

view: 1676

Installation area of ethylene oxide sterilizer requirements site 1. the sterilizer should be placed in a separate room. 2. ethylene oxide sterilization site should stay away from the crowd, scene within 50 meters prohibited open flame fire operation...

Read More

Jun 14, 2023

view: 1241

The ethylene oxide sterilization cabinet also has the following characteristics. Our companys ethylene oxide sterilization cabinet is well designed and well-designed, mainly composed of microcomputer control system, residual gas treatment d...

Read More