Sterilization process and technology of ethylene oxide sterilizer

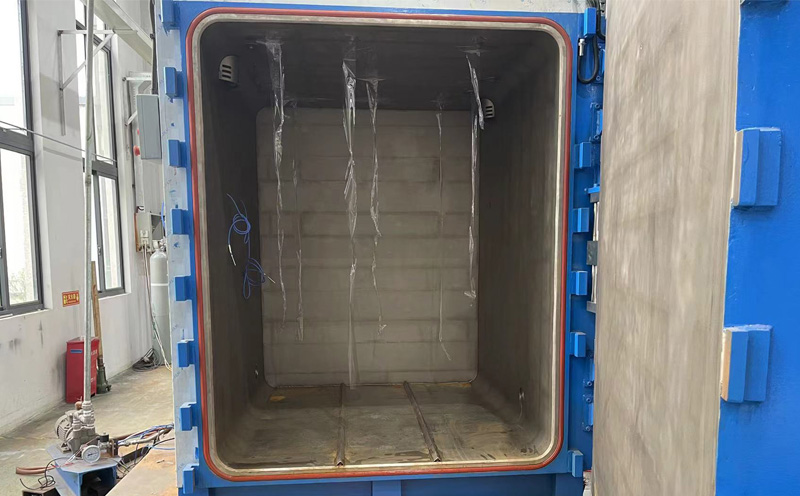

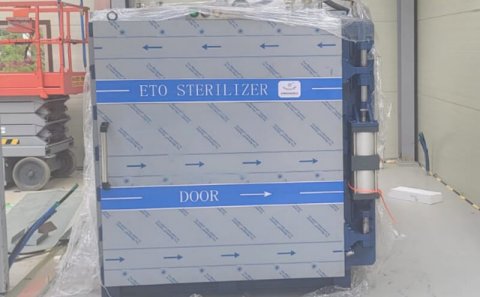

Ethylene oxide gas sterilizer is a machine which uses cold sterilization technology to sterilize through the biological effect of ethylene oxide gas.

The process includes heating, moisturizing, ventilation, sterilization and other steps. Ethylene oxide has low cost and good sterilization effect, but the sterilization cycle and aeration cycle are relatively long.

Commonly used sterilizer specifications and capacities are: 1m3 3m3 6m3 10m3 15m3 20m3 30m3 35m3 50m3, etc.

Do not use vacuum packaging for the packaging bags of articles that need sterilization. It is recommended to add dialysis windows on the packaging.

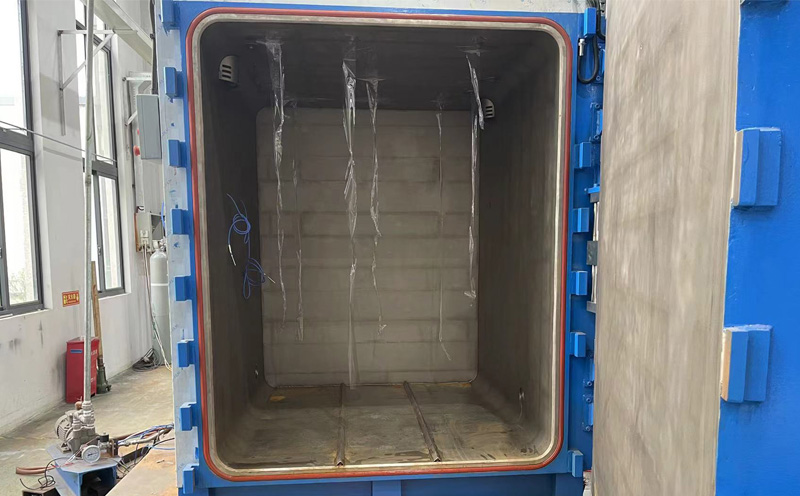

Loading and unloading can be done with trailers and pallets, or with semi-automatic conveyors.

Note:

The products sterilized by ethylene oxide must be removed the gas residue and tested to be qualified before they can be put on the market.

Industrial Sterilization for medical devices and pharmaceutical products

A wide range of medical devices and pharmaceutical products are sterilized by ethylene oxide exposure. Sterilization with ethylene oxide, also known as EO or EtO sterilization, is an established sterilization modality in this industry and provides clear advantages over other processes. Thanks to the low process temperature (below 55°C), the use of EO is far superior to other methods in terms of material compatibility – which means that it is ideally suited for the sterilization of thermolabile products.

However, due to the composition of ethylene oxide, a range of technical and regulatory requirements have to be fulfilled and taken into account. STERISYS is specialized in this domain and we develop and manufacture our equipment in accordance with all relevant standards and guidelines.

As a leading provider of ready-to-use ethylene oxide sterilization systems, we develop innovative and flexible solutions and deliver them to international medical device manufacturers and sterilization service providers.

Key benefits of our solutions:

Safe and efficient sterilization of medical devices and pharmaceutical products;

High degree of flexibility regarding cycle parameterization;

Reliable reproducibility of the sterilization cycles;

Long-term viability and conservation of value, thanks to state-of-the-art components and proven industry standards;

Conformity with all relevant standards and guidelines (ATEX / EN1422:2014 /ISO 11135:2014 / FDA 21 CFR Part /GAMP 5);

Manufacturing of customized sterilization units of all sizes, made to order in our factory in Belgium.

Overpressure and vacuum sterilization systems

STERISYS offers two different EO sterilization processes

the EO overpressure process and

the EO vacuum process.

Based on the requirements of the customer and a process-oriented analysis, STERISYS determines together with the customer the type of sterilization process and the dimension of the unit.

THE EO OVERPRESSURE STERILIZATION SYSTEM

The EO overpressure sterilization process is particularly suitable for small to mid-sized product volumes that are mainly sterilized in their primary packaging.

The overpressure process works for example with a gas blend of 6% EO and 94% CO2. Moreover, in comparison to the vacuum process, the gas holding phase during the sterilization cycle is held at an overpressure of 1.75 bar.

Benefits of the overpressure process:

Due to the low EO concentration, the ATEX guidelines are not applicable (conditions: max. EO gas concentration = 8% and/or LEL < 2.6%).

The entire sterilization process – preconditioning-, sterilization- and degassing-process – can be carried out in the sterilization chamber. No external preconditioning or degassing cells are required.

The EO overpressure sterilizer can be easily integrated into the customer’s existing production flow.

The overall investment costs are lower.

Compared to the EO vacuum process, the cycle times are shorter thus the products reach the market more quickly.

We always start with the product to be sterilized. Based on the material- and packaging-type, product size, intended production volume and purpose of the product, we develop a sterilization unit perfectly suited to customers’ requirements. Beside the sterilization chamber STERISYS also designs and produces the suitable baskets and trolleys to store, transport and especially sterilize the medical devices.

But most importantly, we base these decisions upon how the entire sterilization equipment can be seamlessly integrated into your new or even existing infrastructure and production flow.

The overpressure sterilization system is controlled and monitored by the STERISYS sysREG NT control system. This system offers all functions to ensure an operation in accordance with EN1422 including the appropriate logging of the sterilization cycles.

THE EO VACUUM STERILIZATION SYSTEM

The EO vacuum sterilization process is particularly suitable for a high throughput production. In this case, the medical devices are generally sterilized in their tertiary packaging, means on pallets. These pallets are positioned in one or two rows in the sterilization chamber, oriented lengthwise or crosswise, depending on the space and customer requirements.

The exact chamber size will be jointly defined with the customer, based on the production volume and type and height of the pallets (European, US, customized).

Industrial sterilization of medical devices and drugs

Many medical devices and drugs are sterilized with ethylene oxide. Ethylene oxide sterilization, also known as ethylene oxide or ethylene oxide sterilization, is an established sterilization method in this industry and provides obvious advantages over other processes. Due to low process temperature(

Below 55 ° C), the use of ethylene oxide is far superior to other methods in terms of material compatibility, which means that ethylene oxide is very suitable for sterilization of heat-resistant products.

However, due to the composition of ethylene oxide, a series of technical and regulatory requirements must be met and considered. We are professional in this field, we

Develop and manufacture our equipment in accordance with all relevant standards and guidelines.

As a leading supplier of off the shelf ethylene oxide sterilization system, we have developed innovative and flexible solutions and delivered them to international medical device manufacturers and sterilization service providers.

Key benefits of our solution:

Safe and efficient sterilization of medical devices and drugs;

High flexibility of loop parameterization;

Reliable reproducibility of sterilization cycle;

Long term viability and value protection due to state-of-the-art components and proven industry standards;

Comply with all relevant standards and guidelines;

According to the order of Belgian factory

Size of sterilization device.

Ethylene oxide sterilization

Ethylene oxide sterilization is a low-temperature and low-pressure sterilization method using the biological effect of ethylene oxide gas. During the whole process of heating and moisturizing, the temperature of the whole system is controlled between 10-60 degrees Celsius, and a complete sterilization cycle is about 10 hours. The verification process can be an indicator or parameter release. After sterilization, aeration is needed to remove the residue. The whole process conforms to CE standard, which is a commonly used low-temperature sterilization method.

Specifications of common EO sterilizer equipment: the capacity of the chamber is 78l, 150L, 230L, 1000L, 3m3, 5m3, 10m3, 15m3, 20m3, 25m3, 30m3, etc,or customized production.

matters needing attention:

Whether the material of the goods reacts with ethylene oxide.

The residual ethylene oxide gas needs to be removed after sterilization.

Explosion-proof measures are needed in the sterilization workshop.

Verification method: Using indicator; Parameter release; Biology laboratory.

Overpressure and vacuum sterilization system

Sirisys provides two different ethylene oxide sterilization processes

EO overpressure process and Ethylene oxide vacuum process.

According to the requirements of customers and process oriented analysis, we work with customers to determine the type of sterilization process and the size of the device.

Ethylene oxide overpressure sterilization system

Ethylene oxide overpressure sterilization process is especially suitable for small and medium-sized products mainly sterilized in primary packaging.

For example, overpressure processes work in a mixture of 6% ethylene oxide and 94% carbon dioxide. In addition, compared with the vacuum process, the gas retention stage during the sterilization cycle is maintained

Hold at 1.75 bar overpressure.

Benefits of overpressure process:

Due to the low EO concentration, the ATEX guidelines are not applicable (condition: maximum EO gas concentration = 8% and / or LEL < 2.6%).

The whole sterilization process - pretreatment, sterilization and degassing - can be carried out in the sterilization room. No external pretreatment or degassing is required.

EO overpressure sterilizer can be easily integrated into the existing production process of customers.

The overall investment cost is low.

Compared with the ethylene oxide vacuum process, the cycle is shorter and the product is on the market faster.

We always start with the product to be sterilized. According to the material and packaging type, product size, expected output and use of the product

We have developed a sterilization device which is completely suitable for customers' requirements.

In addition to the sterilization room, suitable baskets and trolleys are designed and manufactured for storage, transportation and, in particular, sterilization of medical devices.

But most importantly, we make these decisions based on how to seamlessly integrate the entire sterilization equipment into your new and even existing infrastructure and production processes.

Overpressure

The bacteria system is controlled and monitored by the control system. The system provides all functions to ensure that operations are carried out in accordance with specifications, including proper recording of sterilization cycles.

Ethylene oxide vacuum sterilization system

Ethylene oxide vacuum sterilization process is especially suitable for high throughput production. In this case, the medical device is usually packed

Disinfect, that is, disinfect on the tray. According to the space and customer requirements, these trays are placed in one or two rows in the sterilization room, vertically or horizontally.

Depending on the volume of production and the type and height of the pallet, the exact chamber size will be determined with the customer.

EO gas concentration commonly used in the process of EO vacuum sterilization:

100% liquid ethylene oxide gas, in barrels.

90% eo-10% CO2 gas mixture.

Due to the high concentration of ethylene oxide, vacuum sterilization equipment must be designed and manufactured in accordance with ATEX guidelines. According to the current technical situation, ethylene oxide

The vacuum sterilization process includes three stages:

1.Pretreatment process: medical devices are prepared for the actual sterilization process (product preheating and humidification).

2.Sterilization process: the product is sterilized under negative pressure in the sterilization room, with appropriate exposure time of ethylene oxide.

3.Degassing process: eliminate the residual EO emission in the exposed products to meet the residual limit value specified in EN ISO 10993-7.

After determining the size of the sterilization room and related equipment, it also supports its customers to implement the whole sterilization equipment (including all related process components - pretreatment and degassing room, gas treatment system, control room, etc.) into the existing or new infrastructure of customers. With our 3D-CAD tools, we can even

User's future sterilization device and the whole factory are visualized in advance.

According to the size and complexity of ethylene oxide sterilization equipment, the system is controlled and monitored by "independent" control software or centralized monitoring and data acquisition system using software. The latter ensures centralized control and monitoring of the entire disinfection plant.

ring

Double sterilization process of oxyethane

The innovative dual EO sterilizer is capable of both overpressure and vacuum sterilization cycles depending on the product to be sterilized.

Other process elements

Pretreated cells

Pretreatment process is a part of the three-phase vacuum process model, which is carried out before the actual sterilization process. In the external pretreatment unit, the product load is being prepared for the following sterilization process. This means that the product is preheated to a uniform temperature in accordance with ISO 11135:2014

And humidify to the predetermined conditions. Its purpose is to create an ideal prerequisite for the actual sterilization process and make the process efficient.

Deaeration chamber

Degassing process is also a part of the three-phase vacuum process model, which is carried out after the sterilization process. The degassing process is used to accelerate the venting of exposed products and eliminate the residual EO emission to reach the limit value specified in EN ISO 10993-7. According to EN 11135:2014 | EN10993-7, the specified ventilation is adopted

And continuously supply fresh air to the degassing chamber to perform the process.

Ethylene oxide gas treatment system

The EO gas treatment system enables customers to process the high concentration EO gas produced by the sterilizer and the high concentration EO gas produced by the degassing room and the transfer room according to the German TA Luft regulation [technical description of air quality control] (EO < = 0.5 mg / m3)

Low concentration waste gas.

According to the sterilization process and the size of sterilization equipment, strisys provides various gas treatment systems:

Electric or pneumatic catalyst, if necessary in combination with "peak shaver" (water buffer tank)

Scrubber system;

Gas incineration system.

Earth observation and monitoring system

Operation of ethylene oxide sterilization device

Personnel must ensure that the maximum concentration of ethylene oxide in the workplace meets local requirements and that the working environment is safe.

We recommend that our customers use the EO monitoring system, which provides considerable assistance in complying with all regulations and specifications and allows the following minimum / maximum EO concentration levels to be detected:

Acceptance level: 0.2 mg / m3 (0.1 ppm)

Tolerance level: 2.0 mg / m3 (1.0 ppm)

This gas chromatography system

It can be equipped with up to 12 measurement channels and 3-level alarm detection for each channel.

Sterisys sysreg software

As one of the main suppliers of EO sterilization equipment, the scope of supply of strisys also includes different process control and monitoring solutions.

According to the size and / or complexity of EO sterilization equipment, strisys

The following two software architectures are provided: independent control architecture uses Siemens TIA portal PLC control platform for each sterilizer and related other process units. Each main process unit has an HMI unit, which allows the operator to control the concentration of sterilization process (process control, monitoring, parameterization, protocol generation, etc.)

The control and monitoring system is based on the Siemens WinCC architecture, which is mainly completed by one WinCC server and one or more WinCC servers.

At present, the company's main business is manufacturing, maintenance and verification of ethylene oxide sterilizer; research and development of disinfection equipment; design and manufacturing of special sterilizer, etc. Bocon is an entrepreneurial platform for a group of young college students who have ideals, knowledge, are willing to struggle and are willing to bear hardships, and technical personnel with rich practical experience of electric power plant. The international and domestic excellent experts in the field of disinfection and sterilization and in the field of ethylene oxide sterilizer manufacturing are the partners and Enterprise Consultants of Unocal. The young people of Unocal work with these excellent experts to study and explore the sterilization theory and practice, and jointly undertake the responsibility and task that the theory and practice of ethylene oxide sterilization in China are at the forefront of the world. According to the requirements of ISO9000 quality system, the company has established a quality assurance system, and strictly manages sales, design, supply, production, installation, commissioning, after-sales service and other links in accordance with the requirements of the system. Our products are not only sold to domestic market, but also exported to Egypt, Malaysia, Indonesia, Saudi Arabia, Nigeria, Tunisia, Vietnam and other countries. According to the requirements of the new iso11135 standard, the company has also developed supporting equipment such as sterilizer preheating room, waste gas treatment device and material transmission system to better meet the needs of users.