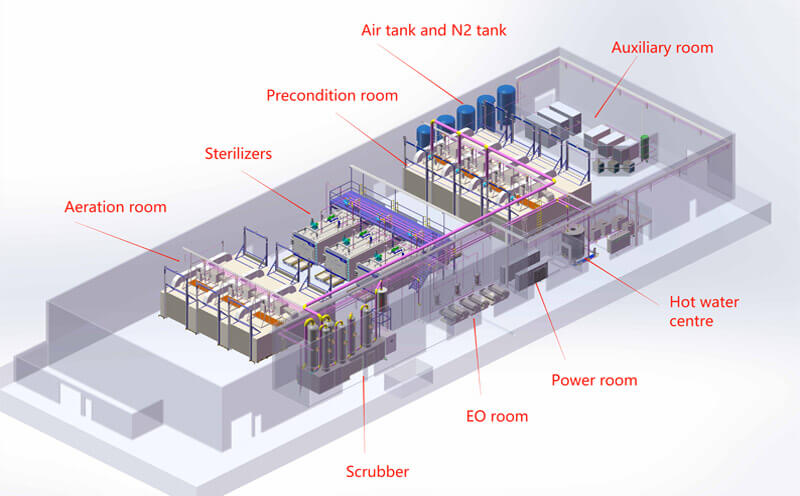

Generally, EO sterilizer needs EO Room, Auxiliary Room and Control Room. Standard requires that the door of EO room cannot lead to sterilization workshop.

The requirements and conditions for ETO sterilization workshop are as follows:

Temperature requirements for ETO sterilization workshop

1. Aeration room.

the temperature in the aeration room is between 35-55 ℃;

2. EO room.

EO room requires you to prepare ex-proof air conditioning for use when the ambient temperature is above 35 ℃. The maximum temperature in EO room is about 35 ℃.

3. Control room

the temperature of control room is around 30 ℃;

4.Sterilization workshop

Sterilization workshop shall ensure the temperature over 10 degrees Celsius.

5. The ventilation system.

Sterilization room, Utility room, Control room, and EO room, the ventilation system has a minimum fresh air replacement frequency of 12 Times/hour based on the size of each room space. kindly prepare it.

Ventilation requirements and conditions for ETO sterilization workshop

EO sterilization requires high safety standards for workshop conditions.

Some requirements for the fresh air system in ETO sterilization workshop are as follows:

The fresh air replacement capacity of the control room, auxiliary room, sterilizer workshop, and EO room all need to meet the replacement volume of 12 times per hour.

For example:

The volume of the sterilizer workshop is L* W*H= Capacity;

The fresh air exchange rate in the sterilization workshop is 12 times the Capacity per hour.

-

In the event of EO leakage, the EO room needs to meet the replacement volume of 20 times per hour or more.

-

Note: Prevent the emitted gases from being sucked into the fresh air system again.

-

In order to ensure smooth fresh air flow, the sterilization workshop(control room, auxiliary room, sterilizer workshop, and EO room) cannot be sealed.

If the fresh air system can meet the above requirements, it is OK, there's no problem.

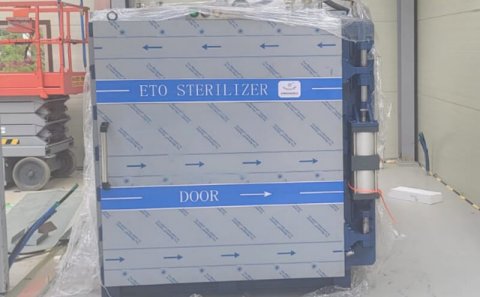

The Explosion proof requirements

Some requirements for the Explosion proof in ETO sterilization workshop are as follows:

In addition, the explosion-proof level requirements for the sterilization workshop are as follows:

-

Ex d IIB T4 Gb

-

Ex: Explosion proof

-

d: Flame proof

-

IIB: Ethylene

-

T4: Surface temperature of equipment ≤ 120°C

-

Gb: Equipment for use in explosive atmospheres due to the presence of gas, with a 'high' level of protection that is not the source of ignition in normal operation or when subject to expected malfunctions, although not on a regular basis.

-

The whole sterilization workshop it is forbidden to open fire, away from the fire. Solid ground level.

-

The sterilizer room should guarantee the well ventilated, use explosion-proof lamps and lanterns and switch.

-

The sterilizer room, explosion-proof axial flow fan, installed in 300-500 mm off the ground.

-

EO room should be well ventilated, avoid direct sunlight, use explosion-proof lamps and lanterns and switch

-

EO room /control room /Auxiliary room height 3000mm(min).

ETO sterilization workshop conditions:

-

The walls of EO room need explosion-proof walls.

-

EO room should be well ventilated, avoid direct sunlight, use explosion-proof lamps and lanterns and switch.

-

Ground bearing capacity level: 2 tons per square meter.

-

The surface evenness shall not exceed 3mm within any 3m length.

-

If the environmental temperature, ventilation, power supply, etc. are provided according to the requirements.

-

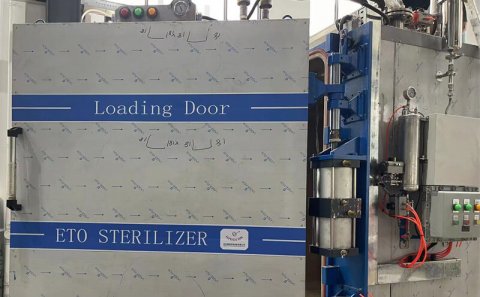

Can the workshop prepare a 350mm deep pit to put the sterilizer into?

The pit can just cover the foot of the sterilizer to facilitate pallet loading/unloading on a flat surface.

If pit cannot be prepared, inclined plates can be used.

If using electric forklift to load & unload, the pit may not be prepared.

-

For installation, the buyer should prepare the industrial power supply, water feeding pipes and water discharging system, EO gas pipes, vapor pipes(may need), EO gas , N2/CO2 gas, and also some to be sterilized product for test.

-

The buyer should provide 2-3 people to cooperate with the installation.

Based on the above analysis, we have gained some understanding of the conditions in the sterilizer workshop and hope it can be helpful to you.

Jun 17, 2025

view: 1396

Precautions for ethylene oxide sterilizer When the ethylene oxide sterilizer is used for sterilization, the temperature, humidity, concentration of sterilization gas and sterilization time in the sterilization cabinet are the important fact...

Read More

Jun 26, 2025

view: 1583

Safety inspection of epoxy ethane sterilizer equipment is complete and in good state Sterilizer used must remain intact state, especially the sterilizer air tightness, cleanliness, integrity. leakage check In the ethylene oxide sterilization, should...

Read More