Five factors affecting the sterilization of ethylene oxide: temperature, pressure, humidity, ethylene oxide concentration and sterilization time.

1、 Temperature

The conventional limit of temperature is usually 37 ℃ ~ 63 ℃, and the suitable temperature is 505 ℃. However, when the temperature is high enough to make the drug play its maximum role, and then the temperature is increased, the bactericidal effect is no longer strengthened.

The determination of sterilization temperature is related to the following factors:

-

1) Products: material, physical and chemical properties

-

2) Stacking: the total loading capacity is 80%, and the loaded articles cannot touch the wall of the cabinet, and there is a certain distance between them

-

3) Packaging: material, size, thickness, loading quantity

-

4) Printing: ensure that the printing quality will not be affected by sterilization.

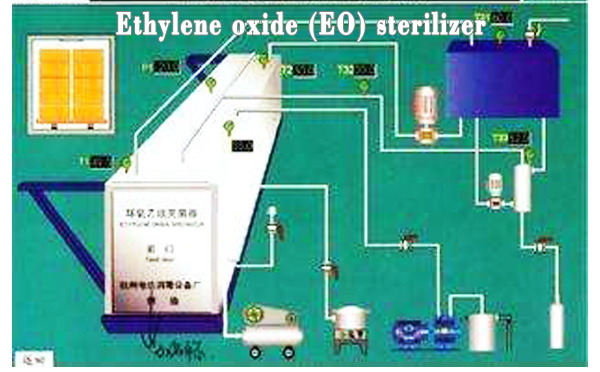

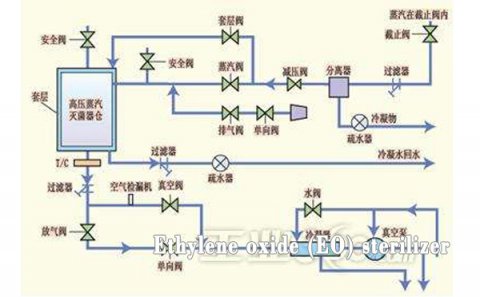

2、 Pressure

The pre vacuum degree determines the amount of residual air, and the residual air can directly affect the ethylene oxide gas, heat, moisture to reach the interior of the sterilized articles, so the sterilization process, especially the vacuum degree before humidification, has a huge impact on the sterilization effect.

-

1) Influence on sterilized articles and their packaging

-

2) Negative pressure and positive pressure sterilization

-

3) Influence on humidity

-

4) Set the vacuum degree and the time needed to reach the vacuum degree

-

5) Vacuum duration (holding pressure).

3、 Humidity

The water content of the sterilized articles, the drying degree of the microorganism itself and the relative humidity of the sterilization environment all have significant effects on the sterilization of ethylene oxide. After vacuumizing and before dosing, the humidity in the sterilizer shall be controlled within the range of 30% rh-80% RH.

4、 Ethylene oxide concentration

300-1000mg / L is a common condition nowadays.

The following factors should be considered:

-

1) Loading capacity of products;

-

2) time required for joining;

-

3) ethylene oxide residue.

5、 Sterilization time

Half cycle method was used to verify the microbial performance, and the shortest effective time (half cycle) of EO without viable bacteria was determined when all other process parameters except time remained unchanged. The action time specified in the sterilization process shall be at least 2 times of the half cycle.

Jun 17, 2025

view: 1552

6 cube ethylene oxide sterilizer 1. The ethylene oxide sterilizer can be installed in the non dust-free workshop. How large area and workshop height should be reserved for the 6 cubic sterilizer? The height of the workshop shall not be less than 3m,...

Read More

Jun 17, 2025

view: 1200

What is parametric release of sterilization? Parametric release is a method of releasing product from sterilization as sterile without the use of BIs, relying instead on a demonstration of conformity of the physical processing parameters to all speci...

Read More