The laboratory is equipped with a 100 level clean operation platform, a 10000 level sterile test and purification room, a bi incubator, and a gas chromatograph for EO / ECH analysis and test.

Biological indicator (BI) test; product sterility test; ethylene oxide residue test.

Run 1 short cycle, 3 half cycles, 3 full cycles,

One short cycle, the product should be sterile, IPCD, EPCD partial positive, and EPCD positive rate is not less than IPCD;

Three and a half cycles, both IPCD and EPCD should be sterile;

2 or 3 full cycles, it is required that the product packaging shall meet the customer's requirements after 2 times of sterilization, and EO / ECH shall meet the iso10993-7 (GB / t16886.7) standard or the customer's requirements.

Ethylene oxide, also known as ethylene oxide, is a colorless liquid at low temperature, with aromatic ether flavor, boiling point of 10.8 ℃, olfactory threshold of 760 mg / m-1064mg / m, density of 1.52; ethylene oxide is flammable and explosive, with a minimum combustion concentration of 3%. Ethylene oxide gas has strong penetration.

Ethylene oxide gas has strong bactericidal power and wide bactericidal spectrum, which can kill all kinds of microorganisms, including bacterial spores. It is a bactericide.

There should be a gap between the upper and lower contents of the articles in the sterilization cabinet (the sterilized articles should not contact the wall of the cabinet), and the articles should be placed in the metal mesh basket or on the metal mesh rack; the loading amount of the articles should not exceed 80% of the total volume in the cabinet.

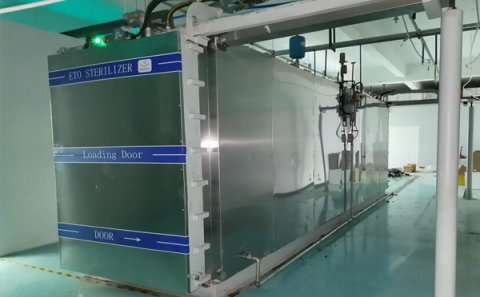

The ethylene oxide sterilizer must be placed in a well ventilated place. Do not place it near the fire source. In order to facilitate maintenance and regular maintenance, 51cm space shall be reserved on each side (including the upper part) of the ethylene oxide sterilizer. Special exhaust pipes shall be installed and completely isolated from other exhaust pipes in the building.

Today, the world leader in ethylene oxide sterilizers using ethylene oxide gas (EO) sterilization, using ethylene oxide sterilizers to sterilize masks makes them safer, more reliable, more convenient and more Economical and more environmentally friendly.

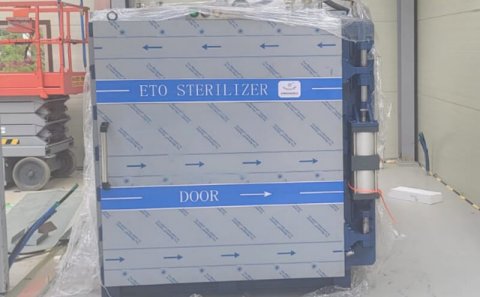

The advantages and disadvantages of various doors for eo sterilizers

About feeding door and unloading door of sterilizers,our company currently has four options, each with advantages and disadvantages, also have their own strengths.

The advantages and disadvantages of Manual door:

Manual door seal does not need inflating, so seal repair and maintenance is relativelyDoor opening way is revolving, saving space around the cabinet. It's suitable for spaceconstrained occasionsSince the cabinet is completely sealed by mechanical seal tightly, so the machiningprocessing is more complex, and cost is higher. It's difficult to repair once theres anyfault. for this reason, this kind of door is not recommended

The advantages and disadvantages of Pneumatic Sliding Door

Pneumatic sliding door uses the inflatable seal. The sealwayis more convenient and reliablePneumatic sliding door is automaticontrolled by cylinders, it's safe and reliablewithout manual applying an external switch,Pneumatic sliding door is the most commonly used door control mode at home andabroadThe biggest drawback is taking up a certain level of space, its not suitable for thespace-constrained occasion

The Advantages And Disadvantages of Pneumatic Revolving Door

Pneumatic revolving door is actually the door with semi-inflatable seal, its a populaway at home and abroad. A cylinder is used to top up the door 100-200mm higher, sole door separates from the door groove, then it can be open and close manually. It'ssuitable for large volume equipment.Pneumatic revolving door is simple in structure, its safe and reliable. Its suitable forted on left and right or top and bottomPneumatic revolving doors sealing way is inflatable seal. It's easy convenient andeliableThe disadvantage is need human being help to open and close the door.

The Advantages And Disadvantages Of Overall Lifting Door:

overall lifting door is explosion-proof electric lifting door. It's rising the overall doorhe top or lowing it to the bottom. It's the most space-saving way. It's full automaticway, does not need any help to open or closeOverall lifting door is also used inflatable sealing method. It's safe and reliablehe overall lifting door is suitable for any cabinet volumeThe disadvantage is the cost is high because many security measures have to beadded

Special NoticeOur quotation price is acquiescent as pneumatic revolving door.If customer would llke to choose pneumatic sliding door, the prlce will decrease5000RMB/doorIf customer would like to choose overall lifting door, the price will increase10000RMB/single pallet door, and 15000RMB/double pallet door.We do not suggest to choose mechanical door.

EO gas: pure or mixed EO gas, the percentage of EO shall not be less than 30%. If a mixture containing less than 30% ethylene oxide is used, the equipment needs to be strengthened

Sterilizer guarantee period is two years. Within the guarantee period, all of the components damaged naturally, our company would mail new components to replace. If you have any problem, you can get our help at any time forever. Our technical can diagnosis the problem from China, we only need you to connect the IPC to internet.

Determine the concentration percentage of ethylene oxide gas.

The commonly used concentration percentages of ethylene oxide include: 100% ethylene oxide, 90% ethylene oxide+10% carbon dioxide, 80% ethylene oxide+20% carbon dioxide, 70% ethylene oxide+30% carbon dioxide, 30% ethylene oxide+70% carbon dioxide, 20% ethylene oxide+80% carbon dioxide, 10% ethylene oxide+90% carbon dioxide, etc.

The lower the percentage concentration of ethylene oxide, the higher the required pressure, the higher the cost of the sterilizer, and the relatively shorter the required aeration time.

Ethylene oxide gas with a concentration exceeding 80% usually requires nitrogen for safety protection, followed by a nitrogen generator.

The EO sterilizer with a concentration range of 70% EO to 30% EO is standard configuration.

The cost of an ethylene oxide sterilizer containing 20% ethylene oxide is 10% higher than that of a sterilizer containing 30% ethylene oxide.

The cost of an ethylene oxide sterilizer containing 10% ethylene oxide is 30% higher than that of a sterilizer containing 30% ethylene oxide.

In some countries, it is not easy to purchase ethylene oxide gas. You can consult your local ethylene oxide supplier to determine the percentage of ethylene oxide concentration that can be purchased.

Jun 17, 2025

view: 1208

Usage method Because ethylene oxide is flammable, explosive and toxic to people, it must be carried out in a closed ethylene oxide sterilizer. Ethylene oxide sterilizer and its application At present, there are many kinds of ethylene oxide...

Read More

Jun 17, 2025

view: 1704

45 cubic eo sterilizer FAQ 1.Internal volume not less than 40 m3 (please provide two options: standard dimension vs customized dimension to full utilise our available space). A: Yes, we provided two schemes, one is a 47m3 sterilizer and the other is...

Read More